There is wisdom in the definition of Six Sigma, which is 3.4 defects per one million opportunities (DPMO), allowing for a 1.5 Sigma shift. But, some

Ford’s Contribution to Just-In-Time

The Just-in-Time (JIT) approach attempts to reduce costs and improve workflow by carefully scheduling material to arrive where needed at the proper

Improving Patient Flow with Lean Healthcare at Flinders Medical Centre

Flinders Medical Centre -- Australia -- implemented Lean over 2.5 years ago and has seen substantial benefit in the way they provide care and the

Lean at Virginia Mason Medical Center

The Virginia Mason Medical Center in Seattle implemented the Toyota Production System in its everyday healthcare operations. This article is

Smooth Flow, Memory Simple, Motion Simple

This article explains how Toyota helps other companies outside of Toyota. There's also some explanation on Smooth Flow and what exactly that

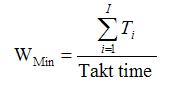

Takt Time in Service Operations: An IRS Tax Operation Example

Takt Time is the maximum allowable time in order to meet demand; Takt Time is the pace by which product is produced and must fall within the Takt Time

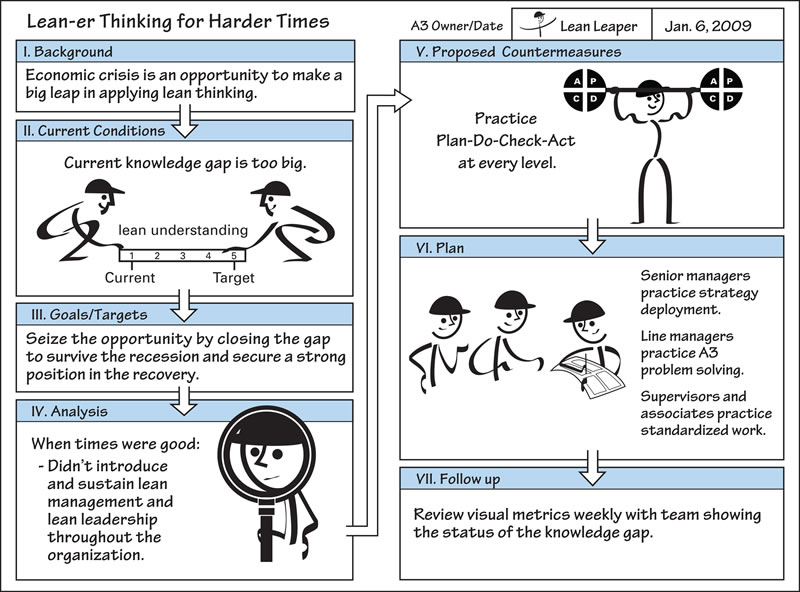

Toyota A3 Report Example [video]

Go here to see a video explanation of the A3 and also to get a Toyota A3 Template Download for Free. This article is about the Lean A3 Problem Solving

Genchi Genbutsu and the Toyota 4Runner

This article entitled "Genchi Genbutsu Toyota 4Runner: A Powerful Go and See Example" is a story of how Genchi Genbutsu was applied in the development

Toyota Word of Mouth Marketing

A VP of Marketing from Wiley Publishers wrote me a few weeks ago and offered me a book to review. I asked why and her comment was that she noticed