In an earlier post, I asked the question: How can Lean and The Theory of Constraints work together? In my attempt to answer that question, I

The Theory of Constraints Fundamentals

This article is part of a series on Lean and the Theory of Constraints. Here is the 3 part series: Lean and Theory of Constraints: An Either/Or

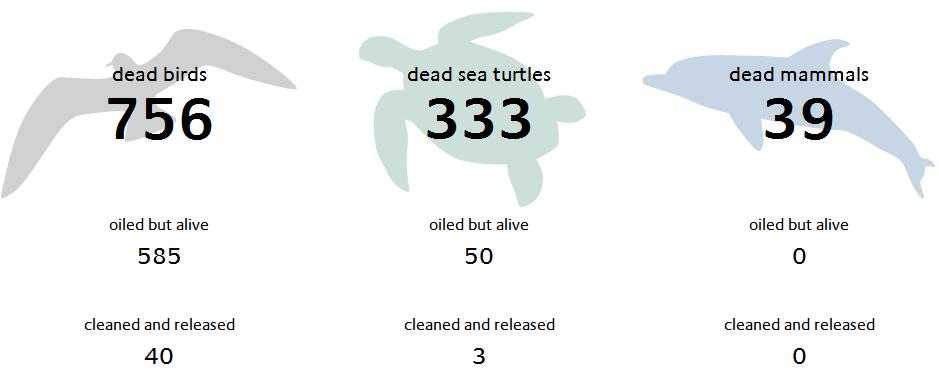

In a Glance: Oil Spill Animals Affected Chart

Similar to the principle of "Make it Obvious", and "Make Problems Visible", this principle is more about delivery than content. The content must be

Implementing Checklists: Centralized or Decentralized

Checklists can be viewed in one of two ways: A formal method to enforce command-and-control (the centralized approach) or, A formal method to

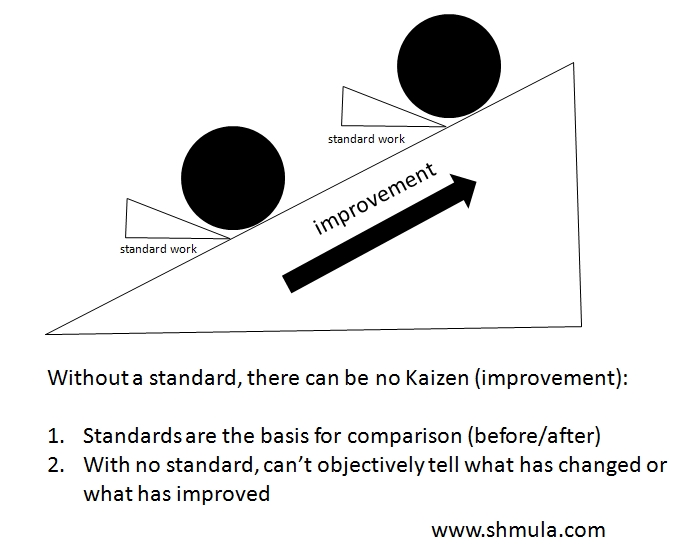

Visual Management Principle: No Standard No Kaizen

No Standard No Kaizen is a common saying in lean and process improvement circles. The principles of Visual Management are related to each other,

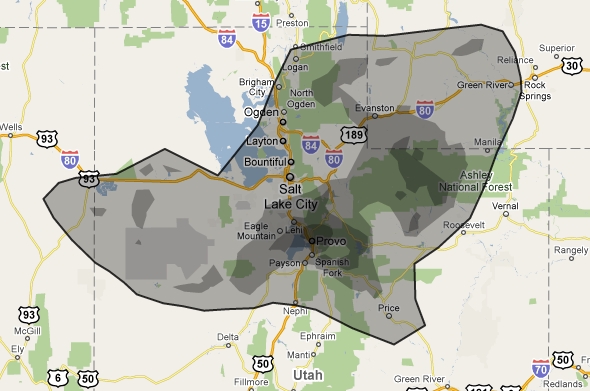

Oil Spill, My Home

A new site gives perspective on the British Petroleum (BP) Oil Spill Disaster [1. In May 1901, William Knox D'Arcy was granted a concession by the

Positive Variance and Standard Work

Standard Work is a very misunderstood concept in Lean Thinking. It's not just about following a set of steps and a hard nosed manager holding his

Visual Management Principles: Make it Obvious

In this post on Visual Management, we'll discuss the principle of Making Things Obvious. I don't remember who said it or how it goes, but that

Visual Management Principles: Make Problems Visible

There's a reason why Kindergarten and preschool classes work - everything is visible. As that famous book said about kindergarten, adults can learn