At work, before you do anything else, go see your customer (internal or external), go see your team or staff - see how they are doing, go see and

Venture Capital and Overproduction

One of the 7 Wastes in the Toyota Production System (Lean) is Overproduction. Within the world of entrepreneurship and venture capital, Overproduction

Solution in Search of a Problem

Most view innovation a big bang type of exercise - or an "aha" moment that came out of nowhere. Indeed, cogito ergo sum - an invention akin to "out

Lean is Easy to Understand, Hard to Do

James Surowiecki [1. source: newyorker.com/talk/financial/2008/05/12/080512ta_talk_surowiecki?printable=true] wrote in the New Yorker a piece about

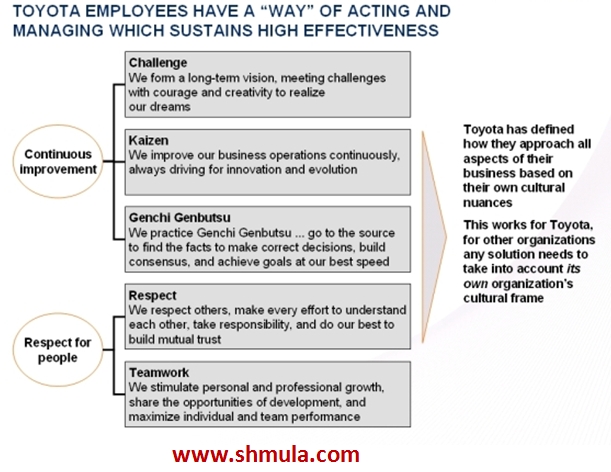

Don’t Forget: Unhappy Employees Unhappy Customers

Unhappy Employees Unhappy Customers - it's a simply profound statement. Simple, but profound. Of the two major pillars in Lean Thinking, one is

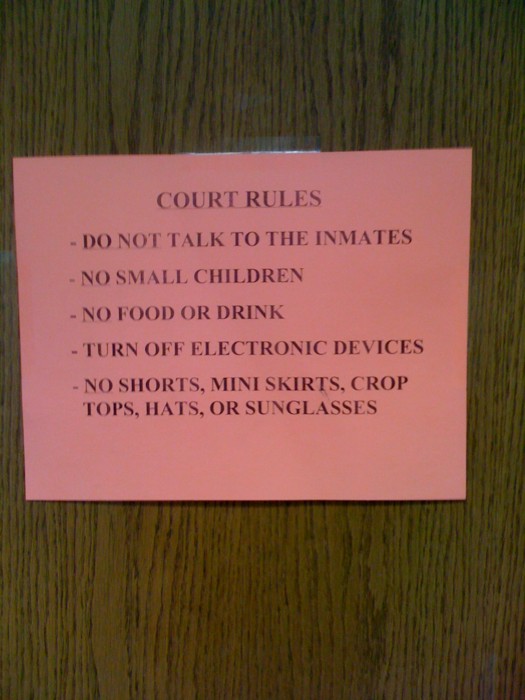

Genchi Genbutsu: Don’t Talk to the Inmates

I write that title with tongue-in-cheek. But, in some cases, corporate leaders act as if employees are inmates and being seen with and talking with

Genchi Genbutsu: Leaders Develop Other Leaders

It's often said that Toyota builds people, then it builds cars. To this end, it's important to consider how Genchi Genbutsu as a principle helps us to

Visual Management: Lawn Mower Maintenance Chart

While shopping at Lowe's, I saw this nice visual management with the aim of answering two questions about lawn mower maintenance: What should I

Lean Culture is about “How”

The Lean subculture talks about the tools of lean, often ignoring principle behind the tool, method, or practice. Another item that is often ignored