Continuing my summary of Yoshihito Wakamatsu's book The Toyota Mindset, today we discuss Taiichi Ohno's view on Automation and Fixing Problems

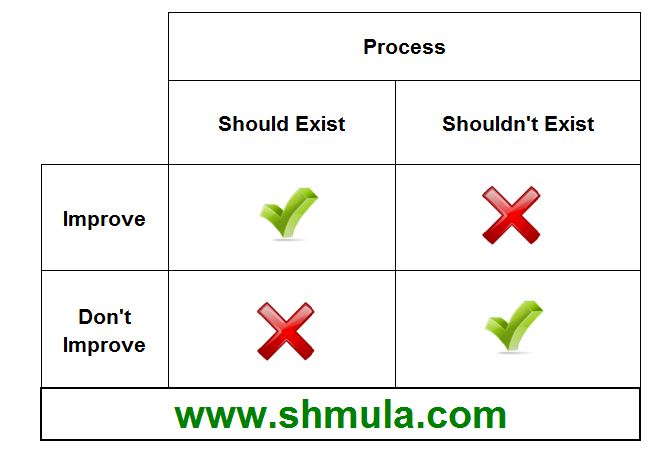

Improving a Process That Should Not Exist is Waste

Arguably, the biggest waste is improving a process that shouldn't exist. Lean is deceptively simple. It's simple, always in retrospect. And,

What Every Lean Transformation Could Learn From Justin Bieber

It's true, I've become a Belieber. No, I'm not into his music - actually, I have yet to hear a complete Justin Bieber song - not yet anyway. No,

Symbiotic Relationship: The 7 Wastes are Not Equal

In this article, we explain the Toyota Seven Wastes Examples - but focus on how each is related to the other. It is astonishing how the principles

Oprahization of Lean Manufacturing

The Toyota Production System is, at bottom, very practical and is based on very measured and systematic experimentation. As a system, this often

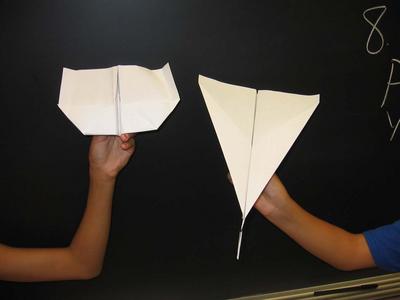

Pull Systems, Push Systems: The Paper Airplane Game

As I teach the principles of Lean Manufacturing to others, I include games that are both fun and also illustrate the concepts in a way that are

Death By a Thousand Cuts

Lean Prevents Death by a Thousand Cuts because Lean manufacturing is the approach of many small improvements over a long period of time. Lean

Lean Six Sigma and Business as Usual

People like events - they're exciting, novel, new, and shiny. Unfortunately, often times after a Kaizen Event, things slip back and return to business

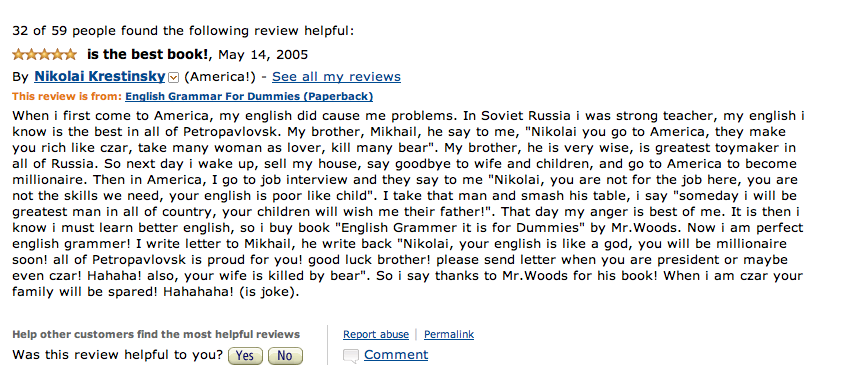

Operational Definition

Sometimes in business - wait - most times in business, we talk pass each other. The other day, I had this very experience in a meeting. We were