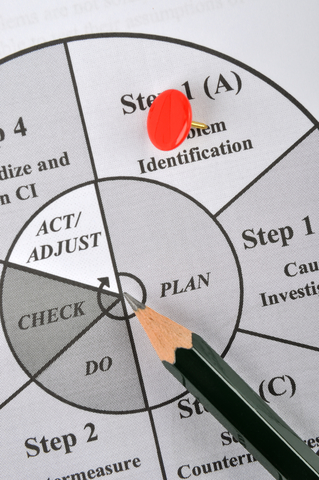

The PDCA (Plan-Do-Check-Act) cycle is one of the most commonly used tools for structuring the work of an organization nowadays, and it has found its

What is the A3 Problem Solving Method?

The A3 problem solving method, like many other concepts related to Lean manufacturing, originated at Toyota and saw active use at the organization for

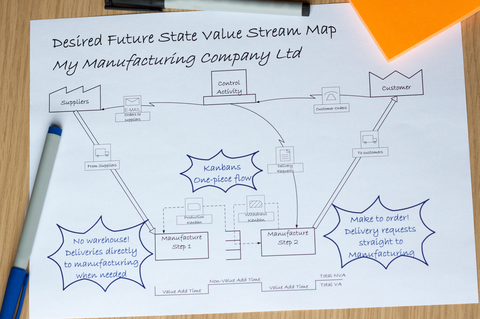

Value Stream Mapping: Basic Steps to Get Started

Value stream mapping (VSM) is a fundamental lean technique that's fallen out of use in recent years for various reasons, but it can still be of huge

Lean Manufacturing: The Basics of Workplace Organization

An efficiently organized workplace is the most fundamental step to guaranteeing the organization's productivity and preparing it for major expansions

What are the Principles of Lean?

Lean principles are all around us nowadays, and it's hard to miss all the talk about it. Yet at the same time, people often find it hard to pinpoint

TED Talk Video – Lean Thinking Applied To All

Can the lean methodology be applied to all areas of our lives beyond the workplace? Can we use the methodology to explore our full potential and make

Achieving a Lean Operation: How Can We Discover Waste?

Waste is probably the most hated and feared word by lean experts worldwide, which makes sense considering that many of the ideas and practices lean is

Lean Manufacturing: The Basics of Time Studies and Work Sampling

Those who've been working with lean methodologies for awhile can probably identify some common patterns in the way problems are approached, and the

Total Productive Maintenance (TPM) and 5S: How They Work Together

Total Productive Maintenance and 5S are two methodologies that seem somewhat distant, but the reality is that applying them effectively at the same